In a previous post, we introduced the subject of durable labels by giving examples of extreme-temperature conditions. Now let’s learn a little more about what makes a label long-lasting. Making sure a durable label continues to perform is a two-fold task.

1. Matching label material to requirements.

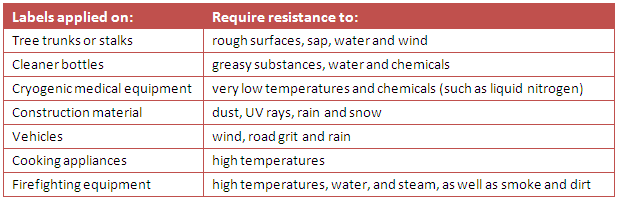

First, the label’s facing, substrate, and adhesive must be matched to its requirements. As a business counting decades of experience in producing labels that stand up to the weather and the test of time, we know as a fact that speciality labels must be designed to match to every potential condition. Here are a few examples of extreme conditions and related label requirements, most of which IMS can provide you with.

2. Matching label application to requirements.

The second part of the task is to match the finished labels to the correct label application. Label applicators, whether or not they are print-and-apply, must be optimized to work with the particular kind of durable labels being used. Even the most durable label is no good if it falls off because it’s been improperly applied.

Also, the label application task must be planned at the very beginning of the design process to avoid a nasty surprise at the end. There would be no use for a nice rounded label if it was meant to be wrapped around a tree trunk, for example. The circumference of the label would have to be broad enough to mould and reach, and even then the information provided would be unreadable. Therefore, if you are not sure about label application, don’t hesitate to contact a specialist.

IMS’s knowledge of specialized label application equipment, along with our experience working with durable labels for industries as varied as agricultural products, transportation, and consumer products generates proven results. In fact, we have specific experience with labels that performed in various extreme conditions with no loss of readability or adhesion!