In my last blog post on the topic of recycled content in paper and cardboard packaging made in Canada, I realized that many terms or expressions might need clarification. Thus, you’ll learn here about the difference between recovered paper and recycled paper.

Recovered paper or recycled paper?

Both expressions seem interchangeable (and are often used for the same thing), but they’re different. It’s quite simple: to be recycled, paper needs to be recovered first. It can come from either domestic collection via recycling bins (post-consumer recycled content) or industrial collection of cardboard parings and scraps (pre-consumer recycled content). The fibres from the paper will be recovered and will then enter the recycling process to become recycled paper.

Part of the paper will be used to make labels, some of which give excellent results when used with inkjet colour printers. We perform tests regularly and we have labels made from 100% post-consumer recycled content in our catalog.

110 tons of recovered paper for 100 tons of recycled paper

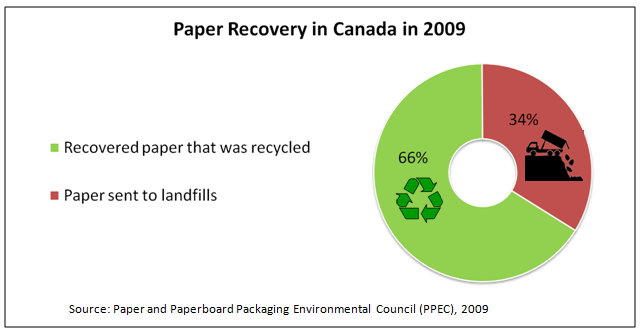

If plants are able to obtain such good results with recycled paper, it’s in part thanks to all of us. The paper and cardboard packaging industry depends on us as a supplier of paper to be recycled. There’s still a good amount of “post-consumer” paper that ends up in landfills though. These fibres are not reusable. In addition, to make 100 tons of recycled paper, plants need 110 tons of recovered paper because the fibres shrink during the pulping process.

As you can see, there’s a significant increase in sustainable development in paper packaging and transformation plants. To give you an idea, in 1994, paper packaging designed for the interior market consisted in an average of 57% recycled content. In 2012, this figure jumped to almost 80%.

Plants will always need virgin fibres to make paper or cardboard because recycled fibres don’t last forever (they get thinner each time they’re recycled). Recycling is still necessary, and not just for paper. The economy depends on us!