Beer in cans is an institution. But a microbrewery cannot always afford and manage printed cans. It requires an inventory management system to store them, and above all, this limits the possibilities of special edition cans and renewal of the packaging.

The solution, as explained in a case study done by Oliver Arian for Pack Advisor, is the shrink sleeve label.

A can is the self-evident choice, so this packaging has become an institution when it comes to beer. Easily transportable, solid, light, recyclable and keeps the drink fresh. The list of benefits is long!

There are also an incredible number of microbreweries and artisans who produce beer, but who cannot afford to manufacture the cans for the reasons mentioned above. And for a beer company to not retail its product in a can means that they are losing market shares.

How can the heat-shrink sleeve label be a solution? Olivier Arian explains that it allows companies to buy “blank” cans (‘silver bullet’, as they say in French) and prepare them for a sleeve to cover the entirety of the container.

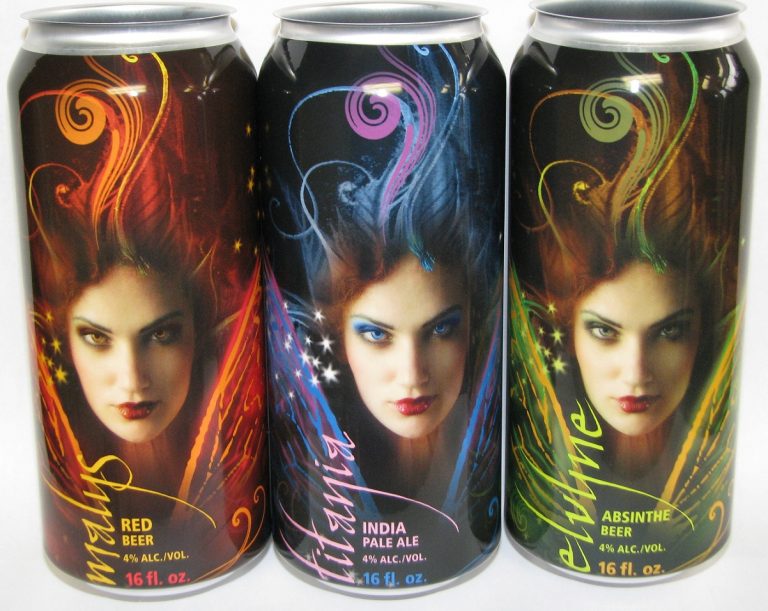

The result? A bobbin with a glossy finish, an identifiable brand and one that distinguishes itself from the competition. Especially at the operational level, it is an easier solution, since the tunnel for the application of the sleeve can stand in almost all parts of the production chain.

In other words, the shrink sleeve is an excellent solution for microbreweries and beer artisans who seek to create cans with a strong personality, and are most visible on the shelves. At IMS, we will be happy to advise you on your sleeve design and evaluate solutions for your industry and your needs, from the design to the printing of your sleeve, with a full project management service.

Source : http://www.packadvisors.com/pages/lookup/Case_Study_Sleeved_Can_Beer_Revolution