Plastic product development has been on the increase for nearly 70 years simply because it is difficult to live without! Each year, we produce 300 million tons of plastics, 8 million tons of which end up dumped into the oceans. On its own, the packaging industry accounts for 40% of the total consumption of plastics. But a new trend involving recovered plastic should have a positive impact on the environment as well as on our industry’s wasteful ways.

Plastics: waste and consequences

The plastics market is extremely profitable and useful to many sectors, applications and products.

However, its overuse and waste have adverse consequences on the environment as well as on humans.

Today, 50% of all plastic produced is thrown away after only one use.

According to a study from PlasticOceans

- The average lifetime of a plastic bag is 15 minutes

- The amount of plastic produced during these last15 years is greater than what has been produced in the whole last century.

In recent years, however, we’ve witnessed the emergence of ecological awareness, as well as new trends in the production and use of plastics.

New trend: eco-friendly production using waste found in nature!

Some companies and industrialists do not hesitate to incorporate recovered plastic in products for a “greener” production.

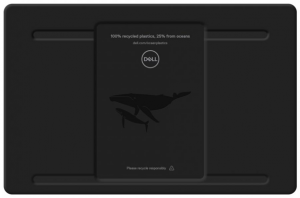

Among these companies are Dell and Procter&Gamble, who have decided to forge ahead with sensible and ecological production.

The objective is twofold

- Continue to use plastic which is a necessary production resource

- Reduce the amount of plastic waste in the ocean by recovering it

How does it work?

Plastic is picked up from beaches, coastal and navigable areas by volunteers, volunteer groups and professional environmental organizations involved in the cause.

The harvested material is then transformed and refined, thus eliminating contaminants that could affect new products.

Procter&Gamble has replicated this production model and has developed a new shampoo packaging, 25% of which is plastic recovered from the ocean.

Also, Dell is using this process in a new packaging system for the XPS 13 2 laptop. The pilot project has managed to recover 16,000 pounds of ocean plastics.

©Dell

With the rise of environmental awareness and more environmentally responsible consumption patterns, this new trend should develop into a new production model.

Did you know?

IMS recycles its industrial waste in collaboration with S3R (a company specialized in reducing waste management costs). This partnership allows us to reduce waste and recycle our raw waste materials from our label production.

For more information, read our blog post “Turning production waste into savings and even profit”.

Would you like to find out more about our eco-responsible labeling solutions? Contact-us!