There are a number of different printing processes. At IMS, one of our areas of expertise is flexographic printing. We recommend this type of printing for long runs, because it is more economical for the customer and the result is impressive.

There are a number of important factors to consider to ensure flexographic printing is successful. One of these is the expertise of the computer graphics team handling your visuals. Our team of computer graphics designers has the expertise to:

- Guide you in converting your file into a printable file for flexography, regardless of the original format.

- Advise you on colours and help you optimize the image for a print job that meets your expectations, while avoiding needless expense.

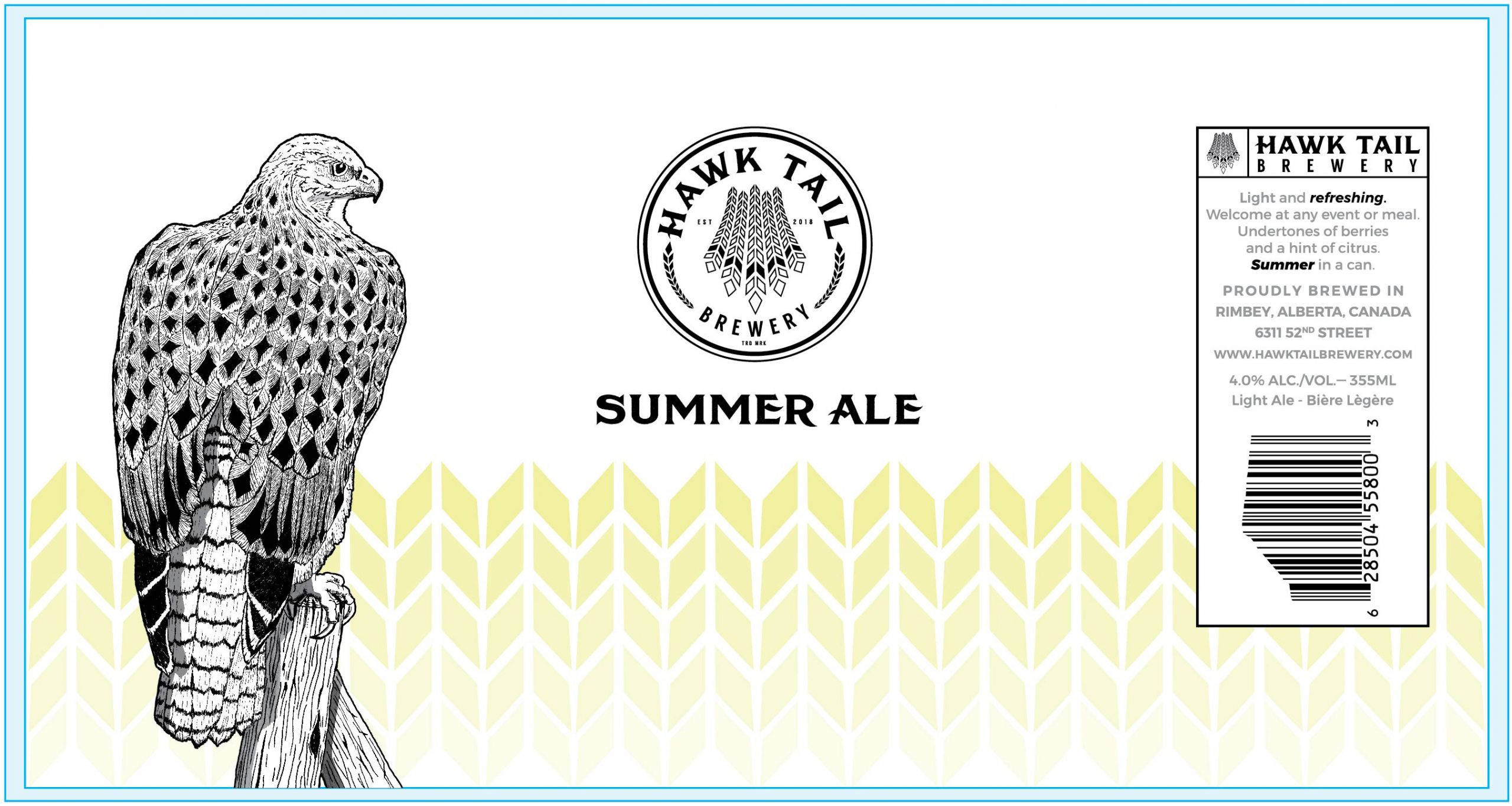

Your graphic design needs vary depending on the complexity of the design and the feasibility of printing. In most cases, a talented team of computer graphics designers will advise you on streamlining colours to save money and improve the rendering. In more complex cases, an agile team of experts will work with you to make changes that will improve the clarity and finish of the printing, while keeping your visual intact. This was the case for Hawk Tail.

Hawk Tail is a major producer of craft beer. It is important that its packaging reflect its incredible beer. As we always do, we took a careful look at the client’s file. Upon close examination, we noticed traces of dust all over the image of the hawk. Working with the client, we cleaned it up, as you can see from the images below.

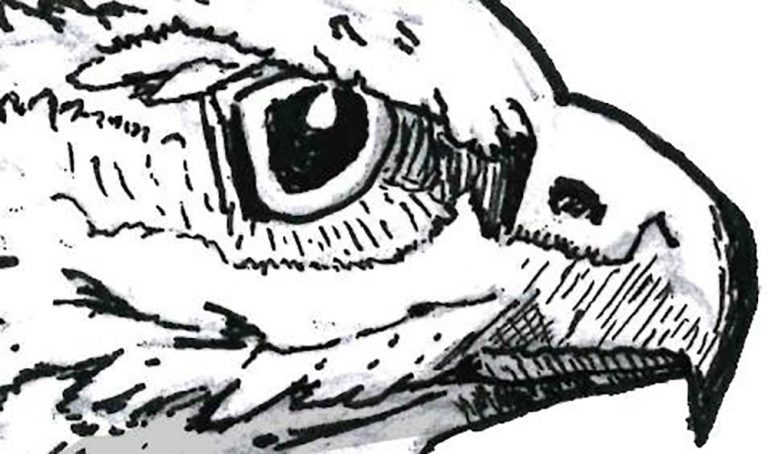

To show you the meticulous work, we have broken down and enlarged the image.

You can see traces of dust between the lines over the entire image of the hawk.

Note the difference with the image below. Our team carefully cleaned up the image and removed all traces of dust. This ensured perfect printing and our client’s complete satisfaction!

We always work with the client, and thanks to the expertise and eagle eye of our teams, we do everything we can to ensure complete satisfaction.

In the case of Hawk Tail, the traces of dust on the image could have created problems when producing plates, because the traces would have been treated as points of unnecessary colour. This would have resulted in additional time to etch everything on the press. As a result, production and delivery times – and no doubt the customer’s bill – would have increased.

Details can make the difference.

At IMS, our strength lies in that difference.

Hawk Tail’s project demonstrates our team’s expertise.

Our expertise

Your labels are the face of your company. With over 60 years of experience, our teams work diligently every day to print labels that exceed your expectations and make your products fly off the shelf!