Optimizing Your Production Line with barcodes

Given over two decades of use at retail cash registers, everyone is familiar with the barcode and how it works. But barcodes do much more than tell a cash register the cost of an item. In most retail operations, product barcodes are also tied to a computerized inventory tracking system. So, if the store has 12 boxes of a certain cereal on the shelf, and six more in the stock room, that information is retrieved by the barcode. When a certain quantity has been sold, it can trigger a reorder.

On a production line, barcodes can do much more than that. A barcode can be fixed to both the finished product and to its component parts. Imagine a total of 10 different parts must be assembled to build a completed piece. Assigning barcodes to each piece and to the whole can make the entire process run much more efficiently and make traceability an easy task.

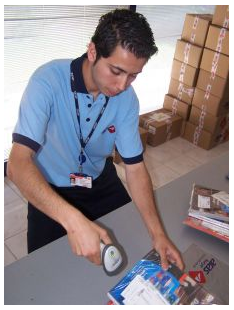

Assembly line operators (or in some cases industrial robots) will scan the barcode on each component as they use it. So, for example, if a parts bin that holds 100 identical components gets down to only 25 components remaining in the bin, the 76th time that code is scanned on the assembly line it can trigger a request of another bin containing 100 parts to be pulled from inventory and brought to the line. In turn, it can also trigger the reorder of another full bin to replenish the inventory. This is particularly useful for JIT (Just In Time) inventory systems typically seen in lean manufacturing operations. The idea is to limit the amount of parts stored in inventory and order on an “as needed” basis.

Not only can each component part be coded in this way, a separate barcode can be assigned to the overall product as it moves down the line and be tracked all the way down. This can provide a manufacturing operation with a wealth of information as it relates to productivity and quality control.

Such systems typically utilize three parts: a printer to produce the barcode labels, barcode readers to scan the labels, and the software to run the system. At IMS, we can help with each of these, and help you make your product management chain a true success.

Usually, the secret to making these systems deliver on their promise lies in the software component. That is why it is important to find a supplier that can work with the software packages you select. Proper setup and configuration is the key to optimal performance, but that is best left as the subject of a future post.

What is your experience with industrial barcode systems? Or, are you now considering such a system for the first time? Let us know. We welcome your comments and questions.