For any busy production line that includes labelling finished products, there’s no question that label applicators are practically a requirement. Good print-and-apply label applicators, which ideally should be custom-designed for your particular solution, can be fully integrated into the manufacturing line in a way that fulfils even the most exacting requirements of precision, speed, and adaptability.

In some cases, production procedures demand highly precise label application, such as when labelling tiny electronic parts without affecting their functioning. In nearly every other case, precision is still important, because a product with a misaligned label does not make the best impression on a potential buyer.

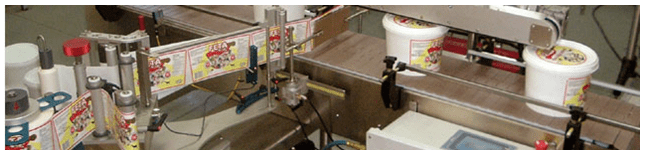

A well-designed label application system is versatile. It will allow your labels to be affixed to the side, or on opposite sides, on the top of the product or bottom, or even on a corner. For example, some of IMS’s equipment even offers labelling solutions for cylindrical containers – from wrapping stations, to heat shrink sleeve labelling, to holding systems equipped with imaging cameras for extremely precise positioning.

Other than the equipment set-up and operator training the main challenge about print-and-apply labelling equipment is coming up with the right solution. It requires both a strong knowledge of the application and peculiarities of its manufacturing processes, and a thorough knowledge of available label application equipment and how it can be adapted and integrated for various needs. It’s the latter that distinguishes a turn-key solution provider from a simple equipment reseller.

Are you facing a challenge with applying labels to your products? We welcome your questions and comments!