When passing over a conveyor, reading a barcode can sometimes be a challenge. The code can be damaged, hidden on every face of the object and in some cases, it passes by the reader too quickly. All of these instances have to be taken into account to prevent “no-read” situations – when the barcode is not read – usually implying manual work and therefore a loss of time and money.

Fortunately, technology is up to these challenges! Nowadays, Cognex barcode readers can read barcodes at an incredible speed and adapt themselves to all uses.

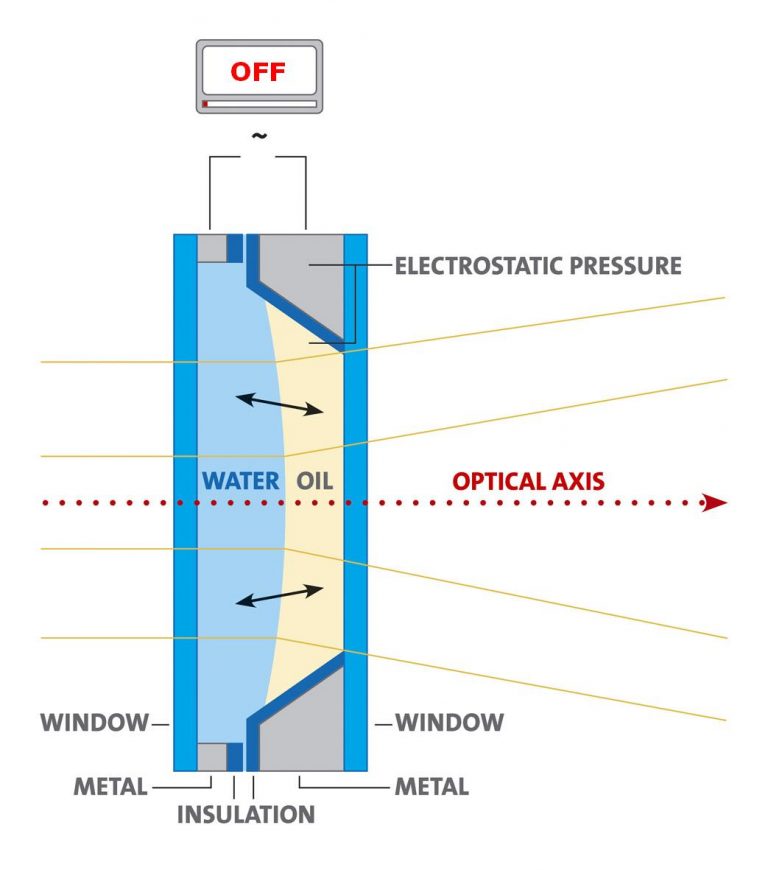

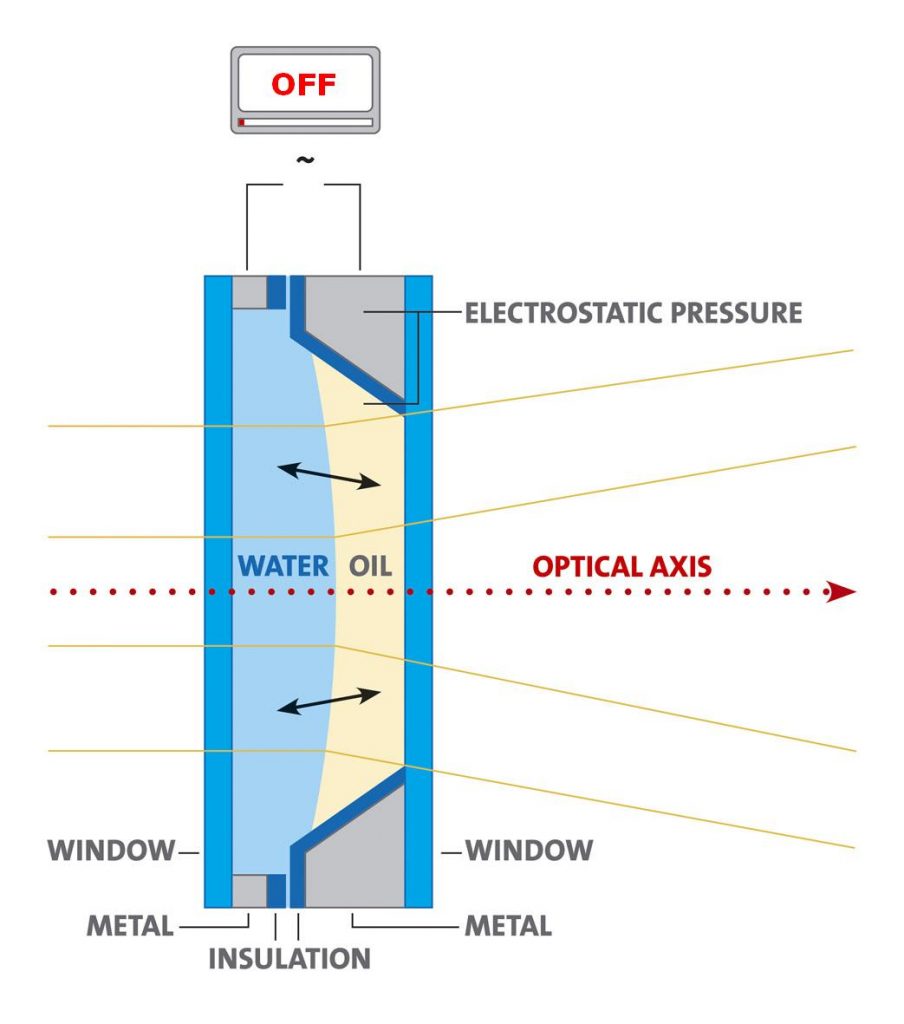

A liquid lens for the autofocus

One of the most common problems is usually the distance between the code and the reader. In other words, this distance will vary on a conveyor carrying objects of different sizes. A traditional reader cannot always focus quickly enough to decode the information on the product. It is therefore necessary to readjust the reader between every object, which takes a lot of time.

The liquid lens is the solution, as it automatically takes focus. In fact, this lens behaves like the human eye and focuses instantaneously. It’s not necessary to adjust the distance between the reader and the barcode anymore; it’s the reader that makes the adjustment by itself. Therefore, the variation of distance due to the different sizes of the objects is not a problem anymore.

Incredible speed

The other challenge for barcode readers used on conveyors is speed. The quicker your conveyor is, the more time you will save. But you need your barcode reader to be able to follow the rhythm. The DataMan products from Cognex are very efficient, as they can take 1000 images and read 120 codes per second (DataMan 503). On top of this, these readers can read on a 360 degree angle.

Amazon for instance, uses this reader. It is also a perfect fit for label printers.

DataMan readers all have the same powerful algorithm which allows them to decode 1-D and 2-D codes quickly. In other words, there is a DataMan reader made just for you.

If you would like to know more about Cognex readers, click here.