2017 might be the year you’ll look at your product and realise that it can be packaged single-serve to increase your sales and profit. Single-serve portions have long-been established in the food packaging market but have been gaining in popularity in recent years for several reasons

- Increased awareness of portions and calorie control

- Increased need for convenience and portability

- Growing awareness of waste and the desire to reduce it

- Rising demand for freshness

Indeed, many companies are now producing individual portions to address these needs and develop fresh sources of revenue. Why not become one of them?

Test runs for single-serve packaging

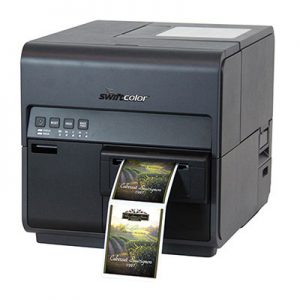

Of course, no company should jump into creating a new product format without test runs to confirm the potential of their new packaging. These don’t have to be expensive to develop, provided you use an appropriate technology, such as digital inkjet printing for example.

Digital inkjet printing

Shrink sleeve labelling

Vacuum-pack labelling

Vacuum packaging is gaining ground. It is getting particularly popular in the meat industry as it can more than double meat shelf-life. It can also contribute to reducing food waste. Manufacturers and retailers have also seized the opportunity to offer single-serve portions. These are gaining popularity in the growing segment of the population that lives alone.

Vacuum-packed meat is typically frozen. It thus requires labels that can remain legible on an uneven surface while frozen, thawed or submerged in water. It is important to consult with a specialist to find a label that fits your application perfectly

Conclusion

If you’d like to investigate single-serve packaging and its associated labelling technologies, don’t hesitate to contact us.

Happy 2017 and happy packaging!